Components Manufactured in the last 3 years

Years In the Industry

Power Presses

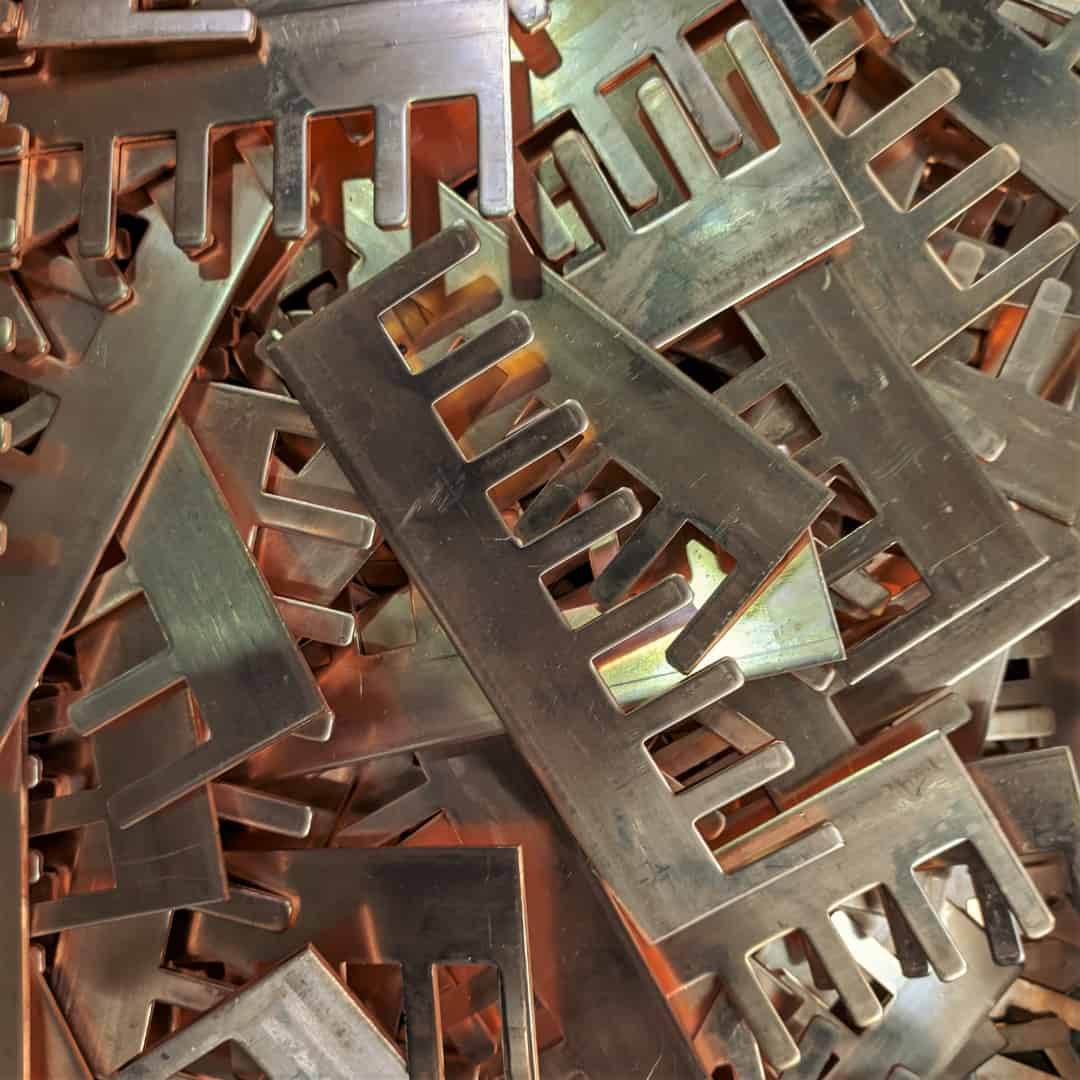

Metal Stamping Supplier

Our presswork design and manufacturing service sits at the centre of our offering, and our engineers are experienced and knowledgeable in serving multiple industries with standard and bespoke presswork alike.

For many years now we have delivered unrivalled metal stamping and metal pressing capabilities, and from our Birmingham based headquarters we continue to supply the quality and precision that you and other professionals servicing customers in other market sectors need to a high specification and at the most competitive price point.

We aim to respond to enquiries within 24 hours!

160 TONNE MAXIMUM CAPACITY

HIGH VOLUME COIL FEED

PROGRESSION PRESSWORK

SECONDARY OPERATIONS

EFFICIENT CAPACITY PLANNING

Metal Stampings for Industrial Applications

At Birmingham Specialities, we offer a vast selection of bespoke metal stampings and precision-engineered components from our centrally located Birmingham workshop.

Our team has the experience and knowledge to design your required components using our in-house tooling design and manufacturing equipment. With a customer-centric approach, we work closely with you to understand your specific requirements and design components that precisely meet your needs.

Metal Stamping in the UK

At BSL, we take pride in being a leading provider of metal stamping services in the UK. With our team of skilled professionals, we deliver top-notch metal stamping solutions that meet the highest industry standards. Our extensive capabilities encompass a wide range of materials, including stainless steel, aluminum, and brass, allowing us to accommodate diverse customer needs.

Whether you require precision components, intricate designs, or high-volume production, our advanced machinery and expertise ensure flawless results. As a trusted partner for numerous industries, we prioritise quality, efficiency, and customer satisfaction. Choose BSL for your metal stamping requirements in the UK and experience superior craftsmanship and reliability that exceed expectations.

Our Presses

One of the key advantages of our facilities is the extensive range of presses we have at our disposal. We have a total of 32 power presses ranging from 6 to 160 tonnes, as well as four air presses and two hydraulic presses. Additionally, we have 14 hand presses, which allow for greater precision and control in smaller-scale projects.

Air Presses

2x 6-ton

1x 5-ton

1x 8-ton

Power Presses

3 x 6-ton

5x 20-ton

2x 25-ton

2 x 40-ton

5x 45-ton

4x 60-ton

3x 80-ton

1x 100-ton

2x 110-ton

3x 150-ton

1x 160-ton

Hand Presses

Hydraulic Presses

Metal Presswork - Your Specific Requirements

Our many years precision metal presswork and stamping means we are able to complete any kind of metal stamping quantity in a variety of materials, length, width and shape formation. We offer large and medium batch production from our centrally-based, fully-equipped West Midlands workshop in Birmingham.

BSL has almost 100 years of experience working with every metal presswork process. The capacity of our 160-tonne machines and experienced and dedicated staff ensure everything from planning to delivering the final result is efficient and you achieve your pressed metal goals.

Materials

We can machine multiple materials depending on your requirements, this ensures that no matter the project, Birmingham Specialities can help bring it to life.

Industries

We provide our range of engineering services to an array of different industries. Applications of our precision components can be found in:

CNC Machining Capabilities

With the use of CAD, Solidworks 3D, EDM and other bespoke manufacturing control systems, our full machining parts factory and capabilities ensure excellence is engineered every time.

FAQ's

What Is A Presswork Machine?

A metal presswork machine is a tool that punches a metal workpiece with great pressure. The tool is placed under the machine’s upper part of the press, which hits the sheet metal and the final workpiece is formed from the pressure.

Presswork machines have been used since the very start of the industrial revolution and became popular for making parts of canal boats, machinery and fixtures for houses and commercial buildings for hundreds of years.

The principles of a metal press machine haven’t changed at all, but the technology has. We now use complex computer-guided hydraulic presses with multiple cutting tools built-in, where once simple weighted presses were used to shape metal. The accuracy and precision of modern metal presswork machines is unmatched.

How Does A Presswork Machine Work?

The lower part of the pressing machine contains the other side of the tool which is the reverse copy of the upper piece of the tool.

Once the press has shaped the metal, it can then be removed and a new piece of metal can be inserted to shape exactly the same. Many machines are capable of performing 500+ cycles per minute for metal presswork, making it a very economical and efficient way of shaping metal.

Many larger manufacturers in the automotive and technology industries use metal presswork as their preferred option for creating their products as once the initial design has been approved and a final product is created, the tooling and materials do not change. This means that the 1000th shaped metal part will be exactly the same as the first.

In other industries, such as aviation, having a benchmark that is adhered to that is millimetre-perfect is paramount to the safety and use of the part. Any custom tooling is kept here at our Birmingham workshop, where a single part can be created for many years. We check tolerances of tooling, so your desired part is always perfect.

What is Metal Stamping?

Metal stamping is a manufacturing process used to create metal parts or components by shaping and forming sheets of metal using specialized machinery and tools. It involves using a press or stamping machine to apply force to a sheet of metal, causing it to deform and take on the desired shape or form. The metal sheet is typically placed between a die (a specially designed tool) and a punch, and the press applies pressure to shape the metal into the desired configuration.

Metal stamping is commonly used in various industries, including Construction, Renewables, electrical products, and more. It can be used to produce a wide range of metal parts, such as brackets, clips, connectors, fasteners, hinges, and panels, among others. The process can be used with different types of metals, including steel, aluminum, brass, copper, and stainless steel.

Metal stamping is highly efficient and cost-effective, as it allows for mass production of metal parts with consistent quality and precision. It offers several advantages, such as the ability to produce complex shapes, high production rates, repeatability, and tight tolerances. Metal stamping is also a versatile process that can be used for both simple and intricate designs, making it suitable for a wide range of applications.

Is there a difference between Metal Stamping and Metal Presswork?

Yes, there is a difference between metal stamping and metal presswork, although the terms are often used interchangeably.

Metal stamping refers to a specific manufacturing process that uses a press or stamping machine to shape and form metal sheets into desired parts or components. It involves applying force to a metal sheet using a die and punch, typically in a single operation, to create the desired shape or form.

On the other hand, metal presswork is a broader term that encompasses various techniques that use a press or similar machinery to manipulate metal sheets or components. Metal presswork can include not only metal stamping but also other processes such as punching, blanking, bending, forming, embossing, and deep drawing, among others.

In essence, metal stamping is a specific type of metal presswork that focuses on using a die and punch to shape metal sheets, while metal presswork is a more general term that encompasses a broader range of techniques that use a press to work with metal materials. Both metal stamping and metal presswork are commonly used in the manufacturing industry to produce metal parts or components for various applications.

Get a Quote Today!

We can provide you with a quote and lead time based on your specific requirements, and we always enjoy the opportunity to assist.

Or contact us at: