Informational/Manufacturing

What is a Sub-Assembly? The Complete Guide

30th March 2023

Introduction:

In the realm of manufacturing, sub-assemblies play a crucial role in the production process. These components are integral parts of larger assemblies, often representing a specific function or a set of related functions within a final product. Understanding the concept and importance of sub-assemblies is vital for optimising manufacturing processes, improving efficiency, and delivering high-quality end products. In this article, we delve into the intricacies of sub-assemblies, exploring their definition, significance, and their role in various industries. Join us as we uncover the world of sub-assemblies and the impact they have on modern manufacturing practices.

Section 1: What are Sub-Assemblies?

Sub-assemblies are individual components or groups of components that are brought together to form a larger assembly or finished product. They represent distinct functionalities within a product and are designed to seamlessly integrate with other sub-assemblies to create a complete and functional end product.

One of the defining characteristics of sub-assemblies is their relative independence within the manufacturing process. Unlike raw materials or finished products, sub-assemblies are created and assembled separately before being integrated into the final product. This modular approach allows manufacturers to streamline production, increase efficiency, and simplify quality control.

Sub-assemblies can range in complexity and size, from simple components like screws, connectors, or sensors, to more intricate sub-systems such as engine modules, control panels, or circuit boards. These sub-assemblies can be designed and manufactured in-house or outsourced to specialised suppliers, depending on the specific requirements and expertise of the manufacturer.

The purpose of sub-assemblies is to break down the manufacturing process into manageable components, allowing for parallel assembly lines and efficient production. By dividing a complex product into sub-assemblies, manufacturers can allocate specialised resources, streamline assembly tasks, and reduce the overall production time. Furthermore, sub-assemblies facilitate product customisation and flexibility.

Manufacturers can create different variants of a product by incorporating specific sub-assemblies, making it easier to meet diverse customer demands. This modular approach also simplifies maintenance and repairs, as faulty sub-assemblies can be replaced or repaired independently without disrupting the entire product.

Section 2: The Significance of Sub-Assemblies

Sub-assemblies hold significant importance in modern manufacturing practices. Here, we explore the various reasons why sub-assemblies play a vital role in the production process:

Enhanced Efficiency:

Sub-assemblies enable manufacturers to achieve greater efficiency in their production lines. By breaking down a complex product into smaller, manageable sub-components, multiple assembly lines can work concurrently on different sub-assemblies. This parallel assembly approach reduces production time and enables faster throughput. Additionally, specialised teams can focus on specific sub-assemblies, leveraging their expertise and maximising productivity.

Streamlined Quality Control:

Sub-assemblies facilitate improved quality control measures during the manufacturing process. By inspecting and testing individual sub-assemblies before integration, manufacturers can identify and rectify any defects or issues at an earlier stage. This proactive approach reduces the likelihood of quality issues affecting the final product. It also simplifies troubleshooting and ensures that only high-quality sub-assemblies are used, enhancing overall product reliability and customer satisfaction.

Customisation and Flexibility:

Sub-assemblies offer increased customisation capabilities. Manufacturers can create variations of a product by combining different sub-assemblies, allowing for tailored solutions to meet specific customer requirements. This flexibility in product design and assembly enables manufacturers to address diverse market demands efficiently. It also enables easier product upgrades or modifications, as individual sub-assemblies can be replaced or upgraded without the need for extensive rework.

Modular Designs:

Sub-assemblies contribute to the development of modular product designs. Modular designs allow for greater flexibility in the assembly process, as sub-assemblies can be easily interchanged or replaced. This modularity simplifies maintenance and repairs, as faulty sub-assemblies can be identified and swapped out without disassembling the entire product. Modular designs also facilitate faster prototyping, product iterations, and upgrades, reducing time-to-market and improving overall product lifecycle management.

Cost Efficiency:

Sub-assemblies can contribute to cost savings in manufacturing. By outsourcing the production of specific sub-assemblies to specialised suppliers, manufacturers can benefit from economies of scale and expertise. This reduces the need for in-house production of every component, allowing manufacturers to focus on their core competencies and allocate resources effectively. Moreover, sub-assemblies enable efficient inventory management, as manufacturers can maintain inventory levels based on demand for specific sub-components, minimising excess stock and associated costs.

Improved Maintenance and Repairs:

Sub-assemblies simplify maintenance and repair processes. With modular designs, faulty sub-assemblies can be quickly identified and replaced, minimising equipment downtime. This reduces the impact on production and improves overall equipment availability. The ability to troubleshoot and repair individual sub-assemblies also enhances serviceability, prolongs the lifespan of products, and reduces maintenance costs.

The significance of sub-assemblies lies in their ability to optimise manufacturing processes, improve quality control, offer customisation options, enable modular designs, and enhance cost efficiency. By leveraging sub-assemblies effectively, manufacturers can streamline operations, deliver high-quality products, and gain a competitive edge in the market.

Read about the disadvantages of sub-assemblies.

Section 3: Applications of Sub-Assemblies

Sub-assemblies find extensive applications across a wide range of industries and products. Their versatility and ability to enhance the efficiency and functionality of complex systems make them indispensable in modern manufacturing. Let's explore some notable industries where sub-assemblies play a pivotal role:

Automotive Industry

In automotive manufacturing, sub-assemblies are crucial for constructing vehicles. Engine modules, braking systems, electrical harnesses, and dashboard clusters are just a few examples of sub-assemblies that are assembled independently before being integrated into the final vehicle assembly. Sub-assemblies enable manufacturers to streamline production lines, improve quality control, and enhance the overall performance and safety of automobiles.

Electronics and Consumer Goods

The electronics industry heavily relies on sub-assemblies for the production of devices such as smartphones, laptops, televisions, and home appliances. Sub-assemblies like printed circuit boards (PCBs), memory modules, display panels, and camera modules are manufactured separately and then integrated into the final electronic products. This modular approach allows for efficient production, easier troubleshooting, and faster product iterations.

Aerospace and Defense

In the aerospace industry, where precision and reliability are paramount, sub-assemblies play a critical role. Sub-assemblies such as landing gear systems, avionics modules, control surfaces, and propulsion systems are manufactured separately and integrated during the assembly of aircraft and spacecraft. The modular nature of sub-assemblies ensures efficient production, easier maintenance, and the ability to upgrade and retrofit components.

Medical Devices

Sub-assemblies are essential in the manufacturing of medical devices, ranging from diagnostic equipment to surgical instruments. Sub-assemblies like imaging sensors, infusion pump modules, and prosthetic components are assembled separately and integrated to create sophisticated medical devices. This approach allows for precise quality control, easier compliance with regulations, and the ability to customise devices for specific patient needs.

Industrial Machinery

Sub-assemblies play a crucial role in the manufacturing of industrial machinery and equipment. Hydraulic systems, control panels, gearboxes, and conveyor systems are examples of sub-assemblies that are independently manufactured and integrated into the final machinery. Sub-assemblies facilitate efficient production, reduce downtime during maintenance, and enable the customisation of machinery for various industrial applications.

These are just a few examples of industries where sub-assemblies are extensively utilised. However, their applications extend far beyond these sectors. From consumer electronics to renewable energy systems, sub-assemblies enhance production efficiency, improve product quality, and enable customisation across numerous industries.

Section 4: Design and Manufacturing Considerations

Designing and manufacturing effective sub-assemblies requires careful planning and consideration. Here, we explore key factors that should be taken into account during the design and production stages to optimise sub-assembly processes:

1) Modular Design Principles: Embracing modular design principles is essential when creating sub-assemblies. By designing sub-assemblies as independent units with standardised interfaces, manufacturers can enhance compatibility, interchangeability, and ease of assembly. Modular design allows for faster production cycles, simplified maintenance, and the ability to customise products by swapping or upgrading specific sub-assemblies.

2) Compatibility and Standardisation: Ensuring compatibility between sub-assemblies and their corresponding components is crucial. Standardising interfaces, connectors, and mounting mechanisms enhances the ease of integration and replacement. Compatibility and standardisation also facilitate collaboration with suppliers, enabling manufacturers to source sub-assemblies from various vendors without sacrificing quality or performance.

3) Scalability and Flexibility: Sub-assemblies should be designed with scalability and flexibility in mind. As products evolve or demand fluctuates, manufacturers need to accommodate changes efficiently. Designing sub-assemblies that can be easily modified, upgraded, or adapted to meet evolving requirements streamlines production processes and reduces costs associated with major redesigns.

4) Quality Control and Testing: Implementing robust quality control measures throughout the sub-assembly manufacturing process is vital. Rigorous testing and inspection protocols should be established to ensure that each sub-assembly meets the required specifications and performance standards. This includes material quality, dimensional accuracy, functional testing, and reliability assessments. Implementing automated inspection and testing procedures can improve efficiency and accuracy in quality control.

4) Quality Control and Testing: Implementing robust quality control measures throughout the sub-assembly manufacturing process is vital. Rigorous testing and inspection protocols should be established to ensure that each sub-assembly meets the required specifications and performance standards. This includes material quality, dimensional accuracy, functional testing, and reliability assessments. Implementing automated inspection and testing procedures can improve efficiency and accuracy in quality control.

5) Automation and Digital Manufacturing: The integration of automation and digital manufacturing technologies can significantly optimise sub-assembly processes. Robotics, computer-aided design (CAD), computer-aided manufacturing (CAM), and digital simulation tools enhance precision, speed, and repeatability. Automation can streamline assembly tasks, reduce human error, and improve overall productivity. Incorporating digital manufacturing technologies allows for virtual testing, prototyping, and optimisation of sub-assembly designs before physical production

6) Supply Chain Management: Effective supply chain management is critical when outsourcing or sourcing sub-assemblies from external suppliers. Maintaining transparent communication, establishing clear specifications, and implementing quality control processes with suppliers ensures consistent and reliable sub-assembly delivery. Collaborating closely with suppliers enables manufacturers to leverage specialised expertise, access cost-effective solutions, and maintain a robust supply chain.

Section 5: Future Trends and Innovations

The world of sub-assemblies is continuously evolving, driven by technological advancements and changing manufacturing demands. In this section, we explore some future trends and innovations that are shaping the landscape of sub-assembly design and manufacturing:

Additive Manufacturing (3D Printing):

Additive manufacturing techniques, such as 3D printing, are revolutionising sub-assembly production. 3D printing enables the creation of complex geometries, customised designs, and lightweight structures with improved strength-to-weight ratios. This technology allows for on-demand production, reduced material waste, and the integration of multiple components into a single printed sub-assembly. As 3D printing capabilities continue to expand, it offers exciting possibilities for faster prototyping, reduced tooling costs, and enhanced design freedom.

Robotics and Automation:

The integration of robotics and automation in sub-assembly manufacturing is set to increase efficiency and productivity. Collaborative robots (cobots) are becoming more prevalent, working alongside human operators to perform repetitive or precision-based tasks. The use of intelligent automation systems, including robotic arms and machine vision, streamlines assembly processes, improves accuracy, and reduces cycle times. As advancements continue, we can expect to see increased automation in sub-assembly production lines, leading to higher output rates and improved overall quality.

Internet of Things (IoT) Integration:

IoT connectivity is transforming sub-assemblies into intelligent components. By integrating sensors and communication capabilities into sub-assemblies, manufacturers can gather real-time data on performance, usage, and maintenance needs. IoT-enabled sub-assemblies enable predictive maintenance, remote monitoring, and optimisation of operations. For example, in industrial machinery, sub-assemblies can communicate their health status, enabling proactive maintenance to minimise downtime and improve reliability.

Intelligent Sub-Assemblies:

With advancements in artificial intelligence (AI) and machine learning (ML), sub-assemblies are becoming smarter and more adaptive. Intelligent sub-assemblies can analyse data, make real-time decisions, and self-optimise their performance based on the surrounding environment or operating conditions. These sub-assemblies can enhance product functionality, improve energy efficiency, and enable self-diagnosis and self-healing capabilities. Intelligent sub-assemblies have the potential to revolutionise various industries, including robotics, automotive, and healthcare.

Digital Twin Technology:

Digital twin technology involves creating a virtual replica of a physical sub-assembly or assembly. This allows manufacturers to simulate, monitor, and optimise sub-assembly performance in a virtual environment. By using real-time data from sensors embedded in sub-assemblies, manufacturers can identify potential issues, simulate scenarios, and optimise performance before physical production. Digital twin technology enables predictive maintenance, reduces downtime, and supports continuous improvement efforts.

Sustainable Sub-Assembly Manufacturing:

As sustainability becomes a priority, sub-assembly manufacturing is moving towards more eco-friendly practices. This includes using recyclable materials, reducing waste generation, and implementing energy-efficient processes. Manufacturers are also exploring alternative manufacturing methods that minimise environmental impact, such as biofabrication and environmentally friendly coatings. Sustainable sub-assembly manufacturing not only reduces the carbon footprint but also aligns with consumer demands for environmentally conscious products.

By embracing these future trends and innovations, manufacturers can unlock new opportunities for efficiency, performance, and sustainability. Additive manufacturing, robotics, IoT integration, intelligent sub-assemblies, digital twin technology, and sustainable practices will shape the future of sub-assembly design and manufacturing, enabling manufacturers to stay competitive and meet the evolving demands of the market.

Conclusion:

Sub-assemblies are the building blocks of modern manufacturing. They enable efficient production processes, enhance product functionality, and contribute to the overall quality of end products. By optimising the design and manufacturing of sub-assemblies, manufacturers can achieve higher productivity, improved customisation capabilities, and reduced costs. As the manufacturing industry continues to evolve, embracing the potential of sub-assemblies becomes essential for companies striving to stay competitive in the global marketplace.

Sources/Useful Resources:

- https://www.deskera.com/blog/sub-assembly-manufacturing/#5-disadvantages-of-sub-assembly-manufacturing

- https://geodis.com/vertical-market/automotive/sub-assembly

- https://link.springer.com/referenceworkentry/10.1007/978-3-662-53120-4_6460

- https://fathommfg.com/blog/3d-printing-assemblies-moving-parts#:~:text=One%20of%20the%20many%20ways,for%20two%20different%203D%20printers.

- https://www.hindawi.com/journals/js/2021/2166075/

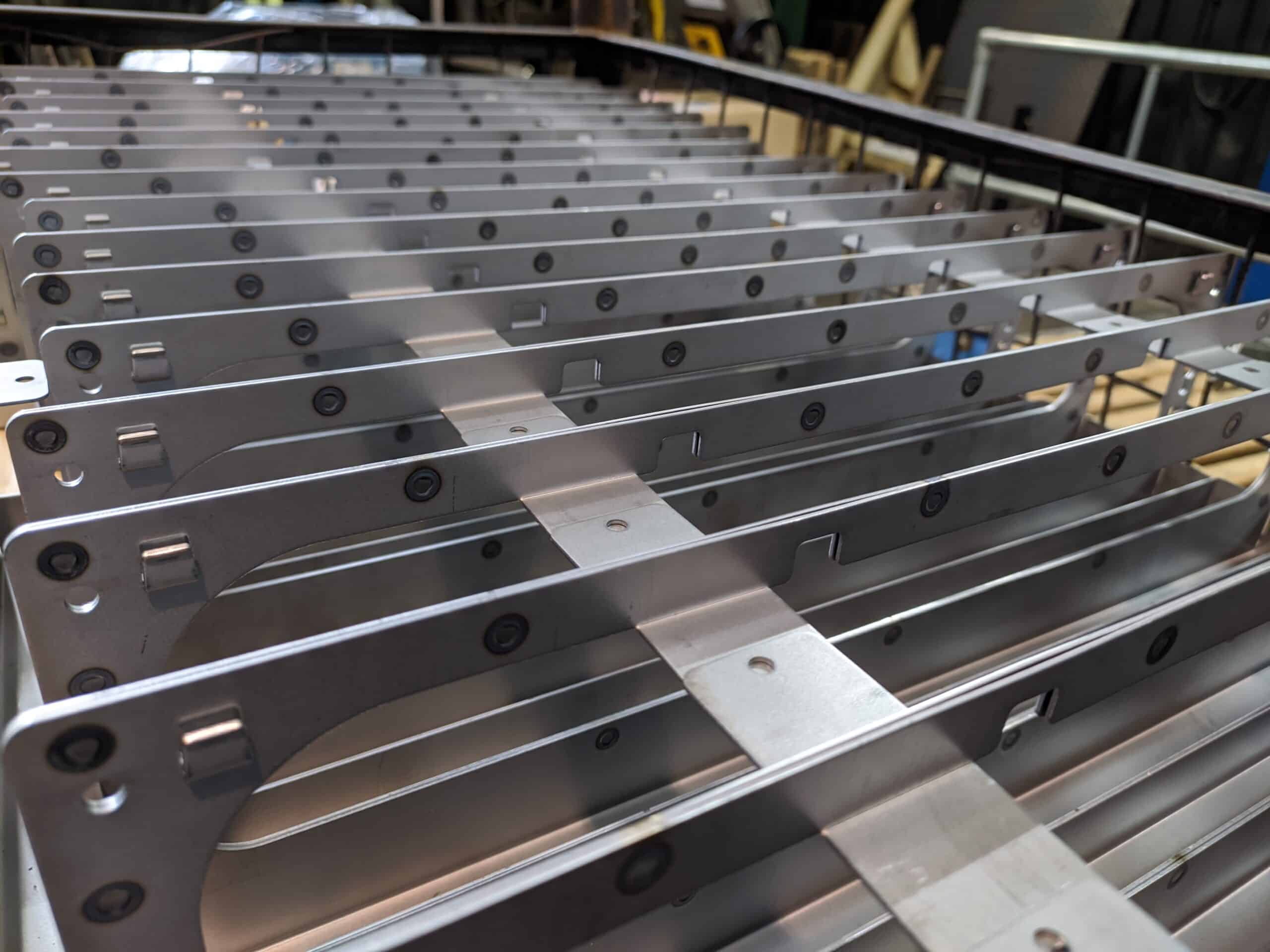

How Can Birmingham Specialities Help?

- This is where we come into play. We have a talented and passionate workforce who boast decades of experience in Sub-Assemblies, Fabrication and Finishing.

- We know how to position specialised equipment to cater for larger and heavier parts, how to minimise waste, how to avoid stress-related distortions or abnormalities, and most importantly, how to rectify problems quickly and efficiently.

- This gives our clients the confidence that they will consistently receive a high quality end product, which is fit for purpose in the sorts of secondary manufacturing desired.

Get a Quote Today!

We can provide you with a quote and lead time based on your specific requirements, and we always enjoy the opportunity to assist.

Or contact us at: